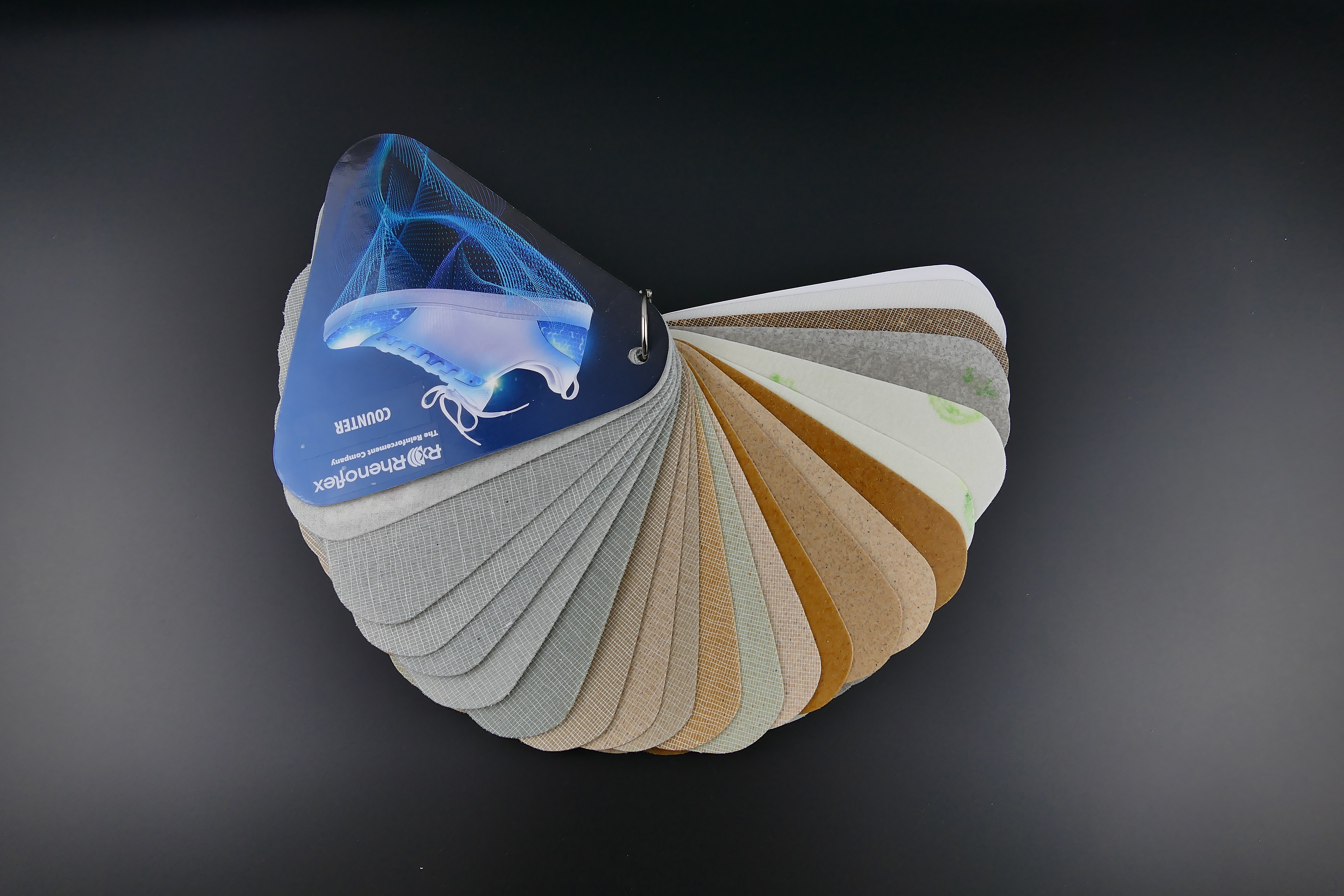

As a cooperation partner of Rhenoflex, we also use the unique Rhenoprint™ process, which enables us to respond to any of your requirements and to manufacture you precisely fitting products - even in small quantities. This is because the Rhenoprint™ process produces powders of the highest quality and under the strictest quality standards according to your specification values in the desired shape, thickness and hardness level, eliminating the need for any punching or sharpening. With the new machine installed in our Pirmasens plant in April 2021, we need 30% less material than for plate goods and there is absolutely

no waste is produced. The most sustainable and fastest way to produce reinforcing materials!